This is how small businesses can help the vulnerable Lake Victoria Basin

The Lake Victoria region, shared by five East African countries (Burundi, Kenya, Rwanda, Tanzania, and Uganda) is home to about 45 million people, many of whom depend on the lake watershed for agriculture, fishery, and livestock production.

The impact of population growth, urbanisation, industrialisation over the last few decades has put enormous pressure on the lake and its surrounding environment, particularly as the lake is the region’s main source of drinking and agricultural and industrial water. And with the population only continuing to grow, this environmental degradation, exacerbated by climate change, is also putting the long-term economic and social prospects of the region at risk, while at the same time making it even more vulnerable to future climate-related events.

Investing in small businesses

Given that small-medium enterprises form the backbone of the regional economy and are often among the highest polluters, the Lake Victoria Basin Resource Efficiency and Cleaner Production (RECP) program set out to engage private-sector investment towards cleaner and more efficient industrial production and supply chains throughout the area. This approach brought measurable benefits both to business and the surrounding environment.

The premise of this NDF co-funded program in partnership with the World Bank (EUR 3.9 million), which ran for two years from 2018 to 2020, was very much about awareness raising and capacity building.

“Companies gained access to trainings, technical support and strategies aimed at enhancing the long-term viability of the region’s eco-system, while boosting its resilience to an increasingly challenging climate,” says Martina Jägerhorn, Program Manager at NDF.

Gender-balanced teams

Even though the demographic structure of industry workers in this region is predominantly male, the teams nominated and put forward by the 136 businesses taking part showed a good gender balance of male and female technical staff members. These teams participated in industry-level trainings and then went back to their companies to strategise and champion project implementation.

Subsequent interventions by companies focused mainly on minimising waste and cutting emissions bringing measurable business benefits while creating cleaner and more efficient workplace conditions. Two success stories have been highlighted below.

Savings reap sweet rewards

Kibos Sugar and Allied Industries (KSAIL) in Kenya annually mills 480,000 tons of sugar cane sourced from small-scale farmers in the Miwani, Nandi, Kericho and Kisumu districts.

“Immediately after the RECP program trainings, we started with the low hanging fruit,” recalls Nicholas Maramba, Safety Manager at KSAIL. “That meant investments in cleaner production and resource efficiency, which are still ongoing.”

The company has made a massive reduction in sugar cane waste, up to 70%, during the collection process. This was done by employing manual labour to pick cane and using machinery to push, grab and load it into the cane carriers for milling. Cane dropping in transit has also been curbed by shifting toward truck transport to replace open sided tractors. KSAIL has also introduced a penalty system for transporters dropping cane in transit from the weighbridges.

“Since this intervention, losses during transportation have decreased by around 35%,” Maramba confirms.

At the mill, working with a female manager and a number of other women from the electrical department, Maramba says the team has been making raw material savings in many other areas too, for example by repairing pump gland leaks and eliminating juice leakage, as well as collecting sugar dust from surfaces and reprocessing it. This also contributes to cleaner and more efficient production.

Before and after shots of pump gland leakage repairs for more efficient production. Source: Kibos Sugar and Allied Industries.

In waste management, sugar mill by-products, normally considered as waste, have become increasingly valued as raw materials, including for future value-added products for local markets. Bagasse is already being used in the boilers to produce high-pressure steam to turn the turbines for energy production, while the excess is being used to produce paper, cartons and tableware. The company also has plans, already at an advanced stage, to use ash, sludge, vinasse and filter mud in the production of bio-fertilizers for local farming. Energy and water savings were also significant across operations, and backed by all these measures, the company has been a recipient of a number of national level awards, and has come to be considered a pioneer in clean efficient energy best practices.

Sugar mill by-products once seen as waste are now being used to make sludge for bio-fertiliser. Source: Kibos Sugar and Allied Industries.

“For us adopting resource efficient and cleaner production practices not only meant more productive use of our surrounding natural resources, but also made good business sense," says Maramba, “as it also brought us ongoing operational cost savings through energy efficiency, use of renewable energy, recycling, and water savings.”

Tea factory brews robust results

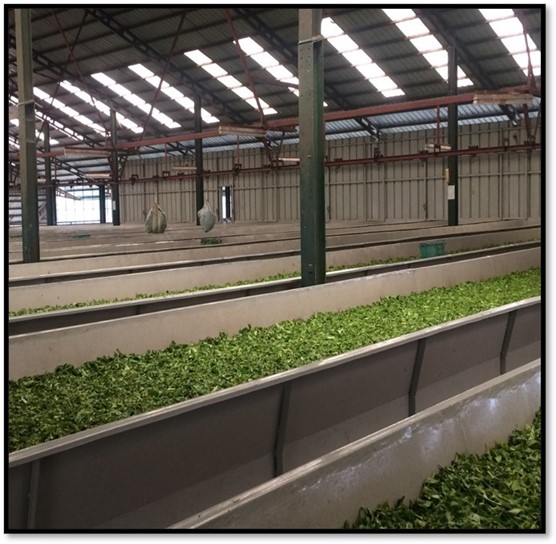

The Nyabihu Tea Factory managed by Rwanda Mountain Tea in North West Rwanda is 123km away from Kigali, the capital city of Rwanda, at an altitude of 2,300m, where it produces cut, tear, curl (CTC) black tea. The company started working with the RECP program from the outset, beginning with basic trainings for staff and factory managers aimed at developing cleaner and more energy efficient tea manufacturing practices. The project team that emerged included five men with engineering backgrounds and three women from the environment, food technology and electrical engineering sectors.

Basic trainings for staff were aimed at developing cleaner and more energy efficient practices. Source: Nyabihu Tea Factory.

“Given the importance of the Lake Victoria basin for the growth and development of our business and community, we felt it was critical to address the causes of the basin’s deteriorating environment and natural resources,” says Octave Vuguziga, Chief Maintenance Officer.

In tea production, fresh tea leaves need to be wilted in an energy intensive fanning process. One successful investment involved the conversion of 10-blade motor fans to 5-blade fans as a fuel-saving measure. Adding variable speed drives (VSDs) to the wilting motors further increased their efficiency.

Converting from 10-blade to 5-blade fans for tea leaf wilting was a successful fuel-saving measure. Source: Nyabihu Tea Factory.

In the plants, the team was also bringing down energy consumption by switching from fluorescent tube lights of 72W to 18W LED lights. They also knocked out brick walls and added transparent strips to the roofs to bring in more natural light, while at the same time lowering the height of the ceiling lights leading to significant annual electricity savings.

Transparent ceiling strips let in more natural light, bringing big electricity savings. Source: Nyabihu Tea Factory.

A simple switch away from burning firewood with bark to fuel their boiler systems also increased efficiency, not only reducing CO2 emissions by 714.48 tons annually, but also keeping the boilers cleaner so they last longer. And in water use, investing in rain water harvesting and a save-water campaign are also contributing to long-term annual water savings.

Investing in rainwater harvesting has brought long-term water savings. Source Nyabihu Tea Factory.

Looking forward, the company plans to invest in solar panels for the factory buildings and to continue its commitment to the circular economy, which includes, among others, supplying used vehicle tyres to shoe-making companies. Backed by all these activities, Nyabihu Tea Factory was awarded best in industry in 2019 by the Rwandan Government.

More work to be done

“Programs like this one show how investing in small business can have long-term benefits for the surrounding environment, while at the same time aligning with companies’ broader economic and social interests,” Martina Jägerhorn says. “The program is also in keeping with NDFs broader efforts in engaging developing countries to shift to a path of low-carbon and climate resilient growth.”

However, despite the success of the RECP program, the scale of industry-related environmental challenges within the basin still far exceeds the available capacity and more work will need to be done.